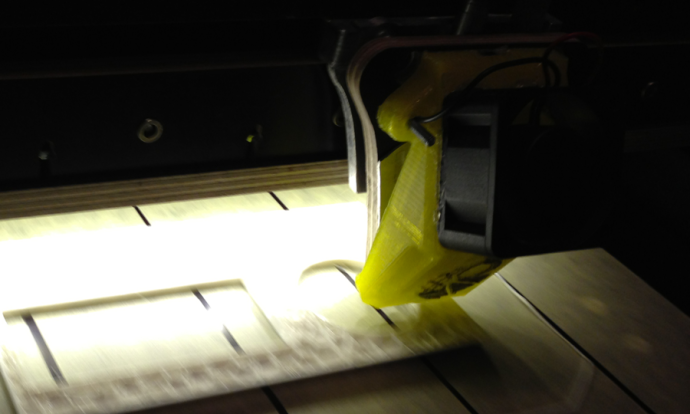

Ever wanted to run your 3D printer directly from SD card? This hack enables you to print from an SD card without the need of a PC.

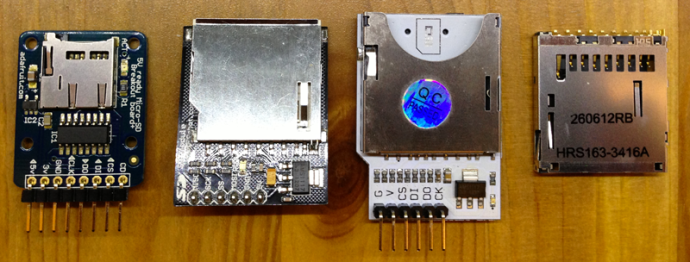

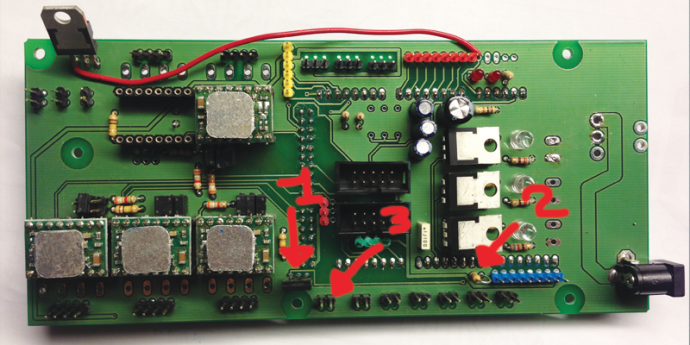

Basically all you need to do is a cable to connect a SD module to your printer, but in this post I’m also going to show you how to create/adapt a SD module in case you don’t already have one.

Despite I’m working on a control panel with some innovative features (look here), I’ve been asked to publish a super-cheap solution that can make you print without the need of a pc (or like in my case a Mac).

Printing without the need of a PC has many benefits, the first one of course it’s that… well… you don’t need a PC.

It could seem a stupid thing to say, but when you have to print a big file and you want to use your pc, you realize it’s not that banal after all 😉

Notice that Marlin firmware already supports a feature called “autostart” to automatically print a file from a SD card, but in my opinion it needs some improvments to make it more reliable for the scope we want.

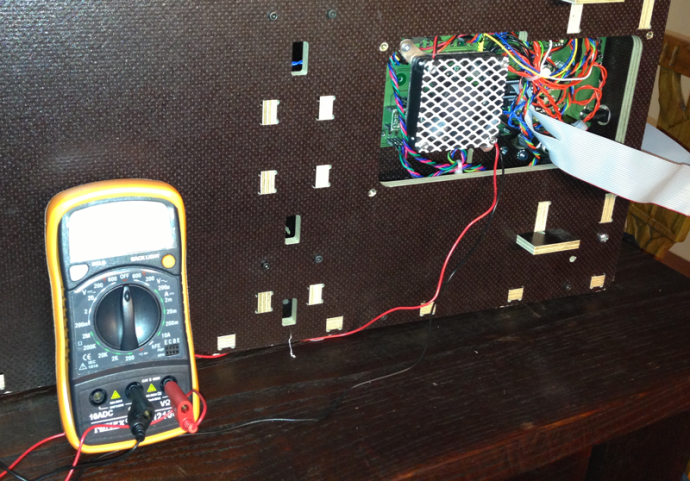

This first post (of 3) will illustrate the “hardware” part of the solution: the SD card reader and how to build the cable to connect it to your printer.

Part two will be about the changes of the firmware, and part three will be about how to provide an enclosure and some improvements for a even better experience.

SKILL: not for a rookie if you want to build your own SD board, otherwise: not difficult at all

TIME: from 1 to 3 hours, depending on the options

TOOLS: a soldering iron, hot glue (optional)

COMPONENTS: 1 SD card module (or components to build it), 30cm of 10 wire ribbon cable, 1 2×5 female Molex connector, 10 female plugs

OPTIONAL COMPONENTS: 1 LED, 1 resistor, 1 push button (see part 3)

Continue reading